As the industrial landscape undergoes a radical transformation powered by the fourth industrial revolution, it’s the innovative frameworks like the Asset Administration Shell (AAS) that are emerging as game-changers. AAS, a digital twin framework, encapsulates the lifecycle and functionality of industrial assets, bridging the gap between the digital and the physical. This holistic digital representation is not a static snapshot; it is a dynamic, real-time reflection that is constantly evolving, mirroring the ever-changing conditions of its physical counterpart. It is this ability to evolve that makes AAS invaluable in the pursuit of operational excellence.

The depth of AAS’s influence can be seen in how it integrates diverse data streams. By weaving together data from sensors, control systems, and operational databases, AAS creates a multidimensional digital avatar. This interconnectedness is more than just a technical achievement; it is the lifeline for industries striving for instant access to actionable data. This continuous flow of information is the essence of what makes predictive maintenance and advanced analytics possible, paving the way for machinery health to be monitored with a proactive, rather than reactive, approach.

AAS: Orchestrating the Fluid Narrative of Industry 4.0

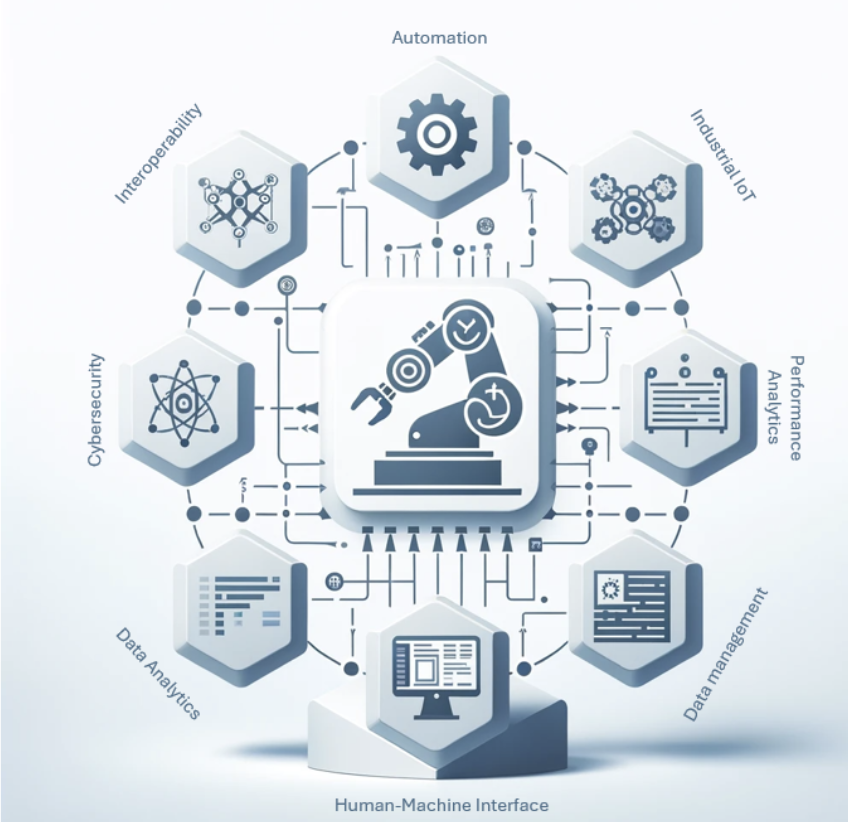

Flowing from data integration to automation, AAS is the backbone of smart factory automation. It is here that the digital narrative of AAS begins to demonstrate its true potential, translating digital control protocols into precise machine operations. This seamless transition from data to action reflects the fluid nature of AAS, a nature that is essential to enhancing productivity while simultaneously reducing the margin for error and operational costs. The narrative then leads us to the challenge of ensuring communication across a diverse array of industrial equipment. AAS addresses this through semantic interoperability, creating a standard language that breaks down barriers between machines. This standardization is not just a facilitator of machine-to-machine dialogue; it is the harmonizer that brings cohesion to an otherwise fragmented industrial symphony, enabling a seamless plug-and-play functionality that is the cornerstone of scalable and adaptable manufacturing ecosystems.

In the heart of this ecosystem is the IIoT, where AAS’s role expands to orchestrating a network of intelligent devices. By enabling these devices to communicate and exchange data, AAS transforms the industrial narrative from one of isolated processes to a story of interconnected chapters, each informing the next in real-time. This transformation is not just about visibility; it’s about creating a new paradigm for decision-making that is as fluid as the data streams it oversees.

Empowering Connectivity: AAS in the Age of Industrial Intelligence

Yet, with every chapter that unfolds in the story of AAS, the plot thickens with the critical aspect of cybersecurity. The digital threads that bind the industrial narrative together are safeguarded by AAS’s cybersecurity measures. This protective layer ensures that the story is not interrupted by external threats, maintaining the integrity of the industrial narrative and reinforcing the trust in this digital revolution.

As we progress, the performance analytics module of AAS comes into the limelight, processing vast quantities of data to extract actionable insights. Here, the story shifts from protection to performance, analyzing patterns to enrich the narrative with foresight and strategic direction.

It is through these insights that the AAS guides industries towards a future marked by continuous improvement and operational finesse. Transcending the boundaries of automation and analytics, AAS also brings a human touch to the industrial narrative through its Human-Machine Interface (HMI). This interface is the point where human intuition meets machine precision, translating complex data into accessible insights.

The fluidity of this interaction is key to maintaining safety, enhancing user experience, and ensuring that human ingenuity continues to play a central role in guiding the course of automated processes. Communicating across this diverse industrial landscape, the protocols of MQTT, OPC UA, and REST are the connectors that bind the different AAS together. Like the currents in a stream, they ensure that data flows smoothly between devices and systems, making real-time updates, cross-platform standardization, and web-based data access possible. These protocols are the undercurrents that sustain the continuous, uninterrupted flow of the AAS narrative. As industries navigate towards a future characterized by sustainability, adaptability, and customization, AAS emerges as the protagonist in a story of industrial evolution. Its architecture is not just about adapting to the current chapter but about writing the next, enabling production systems to swiftly respond to the unique demands of the market.

In weaving together the capabilities of AAS, from data integration to cybersecurity, from IIoT to HMI, the industrial sector is crafting a narrative that is as fluid as the markets it serves. This narrative is not bound by chapters or sections; it is a continuous evolution, a reflection of the dynamic nature of the industry itself. In this fluid journey towards a smarter, interconnected, and sustainable future, AAS stands as the cornerstone, reshaping the very fabric of industrial manufacturing and confirming its pivotal role in the story of Industry 4.0.