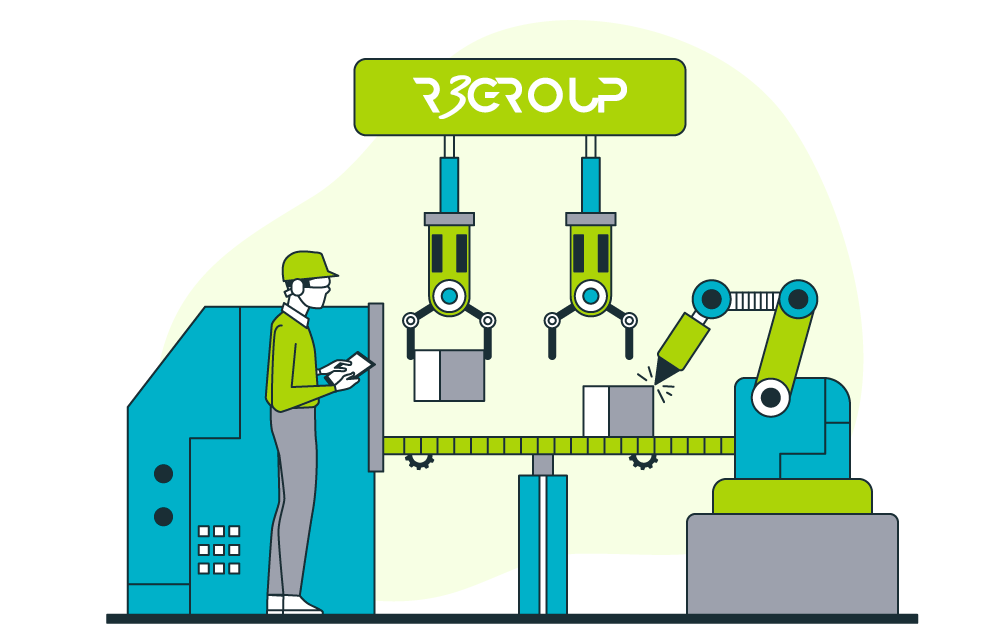

Resilient rapid reconfigurable production process chains

WHAT IS R3GROUP?

OUR OBJECTIVES

Develop rapid reconfigurability in all production levels

Design human-centered solutions

Support the adoption of novel technologies

OUR 5 TECHNOLOGIES PILLARS

R3GROUP will follow the 6 reconfigurability principles to develop technologies in 5 pillars towards resilience through reconfigurability:

AAS-enabled platform for horizontal and vertical integrability for reconfigurability

Develop production tools and technologies, through the reconfigurable machine tool concept

Deploy a digital toolkit supporting rapid evaluation of reconfiguration impacts, using multi-level digital twins

integrate innovative tools to capture the trigger for reconfiguration that provide awareness on the status of the rest of the value chain (supply chain, market)

multi-level monitoring, control, and quality assessment to mitigate the reconfiguration impact.

DO YOU WANT TO KNOW MORE?

Become an active part of this vibrant and multi-dimensional community and share knowledge, create real connections, generate leads and access to new technologies that will improve your manufacturing processes.

DON’T FALL BEHIND!

Stay current with the latest news and about the project. We won’t spam you, we promise!

LASTEST NEWS AND EVENTS

Reconfigurability in Industry: The European Manufacturing Systyems

1. INTRODUCTIONKey elements of process innovation deployment, including people, processes and technologies, are central to a successful implementation of digital transformation. Like in most industries, the transformation of manufacturing is impacted by the skills,...

Reconfigurability in Industry — From Smart Manufacturing to Intelligent Manufacturing by Klaus Beetz

1. INTRODUCTION The move from Smart Manufacturing to Intelligent Manufacturing represents a significant leap forward in how we approach production and operational efficiency. While Smart Manufacturing focuses on using digital tools and automation to enhance...

R3GROUP and FLEX4RES projects’ new paper: Achieving resilience through reconfigurability: The role of digitisation for improved strategy and decision-making for EU manufacturing industries

The concept of resilience has gained renewed attention in EU policy since the Covid-19 crisis. But what does resilience mean in the context of manufacturing? Broadly, it refers to the ability not only to withstand and cope with challenges but also to undergo...

SUPPORTIVE PARTNERS

KEEP ME POSTED