1. INTRODUCTION

Over the past decade, the global production landscape has been reshaped by post-pandemic shocks, volatile energy prices, and rapidly changing demand structures.

The European manufacturing industry has had to confront the necessity of strengthening its resilience against such systemic disruptions (IMF, 2025).

Efficiency and cost competitiveness alone are no longer sufficient; resilience—defined as the ability to resist, adapt, and recover from shocks—has become a strategic imperative.

In this context, the concept of resilience emerges as a meta-paradigm for sustainable industrial growth and competitiveness.

The European Institute of Innovation and Technology (EIT Manufacturing, 2025) positions resilient manufacturing as the foundation for industrial autonomy and strategic robustness.

2. Conceptual Background: Defining and Measuring Resilience

In engineering terms, resilience refers to a system’s capacity to maintain functionality, adapt, and recover rapidly after a disruption (Kusiak, 2020).

It is not a static property but a dynamic capability shaped by feedback, learning, and reconfiguration processes.

Quantitative models define resilience through four parameters:

(1) pre-disruption performance,

(2) performance degradation,

(3) recovery time, and

(4) new equilibrium level (Alexopoulos et al., 2022).

These metrics provide an operational framework for assessing resilience in manufacturing systems.

3. Current Trends in European Manufacturing

3.1. Geopolitical Fragility and Nearshoring Trends

European manufacturers are rapidly embracing nearshoring strategies to reduce dependencies created by long and fragile supply chains. According to Capgemini (2025), the share of European producers investing in nearshoring increased from 42% in 2024 to 56% in 2025.

This shift enhances regional production autonomy and strengthens supply chain resilience.

3.2. Digital Twins and Industry 4.0 Integration

Digital twins-virtual replicas of physical production systems-enable real-time simulation,

risk forecasting, and resource optimisation. They enhance anticipatory resilience by allowing predictive responses to disruptions (Accurate Project, 2025).

European industries increasingly employ digital twins not only for efficiency but as predictive resilience tools.

3.3. Autonomous and Modular Production Architectures

The R3 Group (2025) highlights that reconfigurable production systems, built upon autonomous modules, support self-organising manufacturing lines.

This modularity enables rapid reconfiguration in response to component failures or market fluctuations, reinforcing the adaptive dimension of resilience.

4. The Interaction Between Resilience and Reconfigurability

Reconfigurable Manufacturing Systems (RMS) form the technological foundation of

industrial resilience.

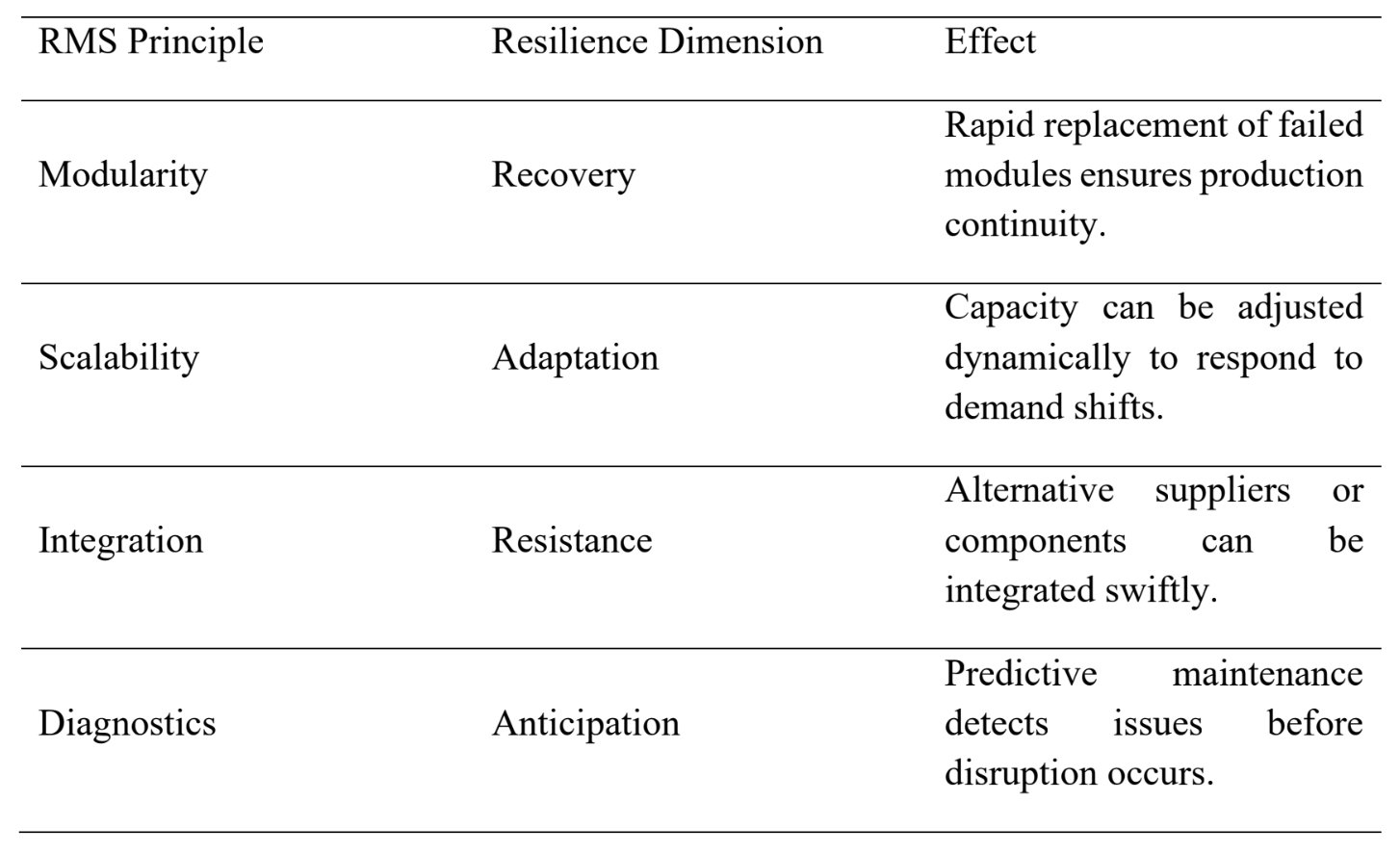

Their core principles-modularity, scalability, integration, and diagnostics-correspond

closely to different resilience phases:

This alignment illustrates that resilience is not a passive defense mechanism but a proactive capacity for systemic transformation. For European industries, RMS embodies not just flexibility but strategic autonomy (Milisavljevic-Syed, 2024).

5. Policy Implications

Resilience-oriented industrial policies must extend beyond large corporations to include small and medium-sized enterprises (SMEs).

At the EU level, the following strategies are crucial: (1) standardisation of modular components, (2) democratisation of access to digital twin technologies, and (3) enhanced R&D incentives for RMS-based innovation (EIT Manufacturing, 2025).

These initiatives will enable Europe to strengthen both technological and geopolitical resilience.

6. Conclusion and Future Directions

In European manufacturing, resilience has evolved from a crisis response mechanism into a new philosophy of production.

Digitalisation, modularity, and AI-driven automation are the operational pillars of this paradigm. Reconfigurable Manufacturing Systems (RMS) provide the technological realisation of this philosophy.

Future research should explore the intersection between resilience and sustainability, particularly how circular economy principles-reuse and repurposing be embedded within resilient manufacturing systems.

Resilience thus emerges not only as an economic advantage but as a comprehensive framework for sustainable and adaptive industry in Europe.

References

- Accurate Project. (2025). How Digital Twins Are Reinventing Resilience in European Manufacturing.

- Alexopoulos, K., Anagiannis, I., & Nikolakis, N. (2022). A quantitative approach to resilience in manufacturing systems. International Journal of Production Research.

- Capgemini/Aberdeen Investments. (2025). Producing in Europe for Europe: Why Reindustrialisation is the Next Frontier.

- EIT Manufacturing. (2025). European Manufacturing in a Shifting Geopolitical Landscape.

- IMF. (2025). Rising to the Challenge: Europe’s Path to Growth and Resilience.

- Kusiak, A. (2020). Open Manufacturing: A Design-for-Resilience Approach. International Journal of Production Research.

- Milisavljevic-Syed, J. (2024). Realisation of Responsive and Sustainable Reconfigurable Systems. International Journal of Production Research.

- R3 Group Project. (2025). Reconfigurability in Industry: From Smart to Intelligent Manufacturing.

ABOUT THE AUTHOR

Fatih Al – R3GROUP Ambassador