1. INTRODUCTION

The move from Smart Manufacturing to Intelligent Manufacturing represents a significant leap forward in how we approach production and operational efficiency. While Smart Manufacturing focuses on using digital tools and automation to enhance productivity, Intelligent Manufacturing goes a step further by integrating advanced AI, machine learning, LLMs, and advanced data analytics to enable systems that can learn, adapt, and optimise in real-time.

In Intelligent Manufacturing, machines and processes not only collect and share data but also interpret and act on it autonomously. This shift enables predictive maintenance, enhanced quality control, and greater adaptability to changing market demands or disruptions. The result is a more agile, efficient, and sustainable manufacturing ecosystem, where operations are driven by connected workers, real-time communication, and intelligent decision-making, rather than simple automation.

Intelligent Manufacturing is not just about digitising factories — Intelligent Manufacturing is about making them intelligent. This transition is crucial for businesses seeking to stay competitive in an increasingly complex and fast-paced global market.

2. CONNECTIVITY IS KEY

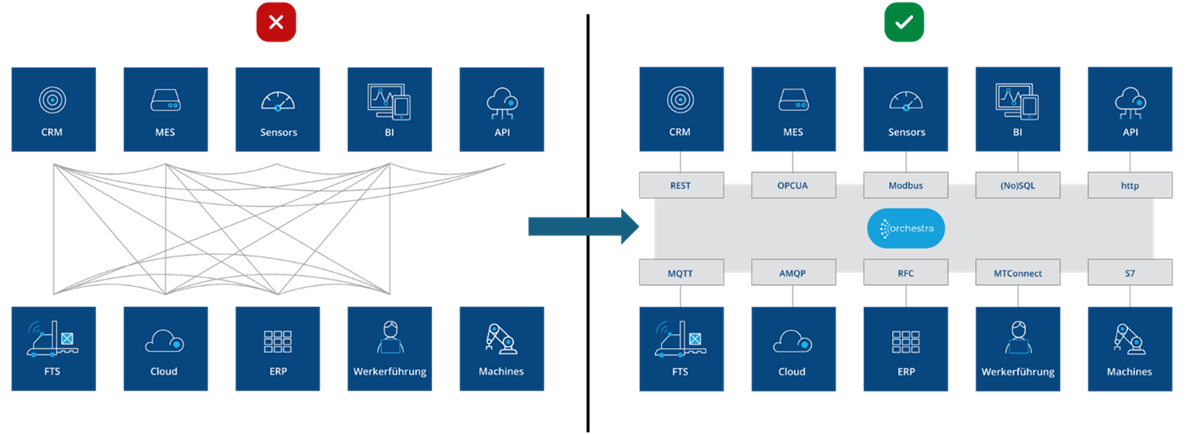

A key factor in the transformation from Smart to Intelligent Manufacturing is not the data itself, but the intelligent connection of that data. By linking machines, systems, people, and products through digital networks, manufacturers gain real-time visibility across their operations. This transparency enables faster decision-making, predictive maintenance, and seamless coordination along the supply chain. For example, the Orchestra tool by Soffico connects all relevant IT systems and acts as a “data conductor,” ensuring that the right data is in the right place, at the right time, and in the required quality and format.

Figure 1. From Spaghetti interfacing to a central data hub

In essence, connectivity transforms isolated machines into intelligent ecosystems, paving the way for intelligent factories that are agile, efficient, and resilient in the face of market change.

3. RECONFIGURABILITY IN PRODUCTION SYSTEMS

In today’s rapidly evolving manufacturing environment, consumer demand has shifted decisively toward individualized products. Traditional mass-production approaches—optimized for volume and uniformity—are becoming increasingly insufficient. In contrast, reconfigurable manufacturing systems (RMS) present a promising paradigm, enabling rapid adaptation and delivering flexibility — a capability no longer optional but essential for meeting personalized demands. Reconfigurability refers to the ability of a production system to be rapidly adjusted in both capacity and functionality in response to changing demands.

Unlike traditional lines, which are fixed and optimized for one product, reconfigurable systems are modular, scalable, and adaptable. Reconfigurability is one of the most important cornerstones of Intelligent Manufacturing. While flexibility is about producing a range of different products or variations, reconfigurability goes deeper—it allows the system itself to change its structure, tools, and workflows to meet evolving requirements. In this way, reconfigurability makes the production system intelligent by moving from pre-determined fixed production lines towards autonomous, self-organized production cells connected by highly flexible transport solutions.

4. THE R3GROUP EARLY ADOPTER PROGRAMME (EAP)

The R3GROUP project is an initiative funded by the European Union’s Horizon Europe programme that aims to support the resilience of European manufacturing firms by providing tools to enable rapid reconfigurability. The general objective of R3GROUP is to develop and demonstrate resilience strategies for reconfiguration in different manufacturing sectors. Further the R3Group is developing human-centred solutions and put a special focus on reskilling to support the adoption of novel technologies.

The Early Adopter Programme (EAP) of the R3Group is a unique opportunity for manufacturers and tech stakeholders to test R3GROUP technologies before they hit the market. The programme offers external SMEs the opportunity to get access to innovative reconfigurable technologies without any investment. Early adopters will gain insights, early access, and influence over the final tools and solutions

5. CONCLUSION

As customer demand for individualised products continues to grow, production systems must evolve beyond traditional mass production models. Flexibility, enabled by reconfigurable production systems, is emerging as a crucial capability for manufacturers who wish to remain competitive. Connectivity is the foundation and upfront investments in modular hardware/software, digital twins, and skills are substantial. But the benefits of responsiveness, variety, and efficiency make the transition worthwhile. In the era of mass customisation, companies that embrace reconfigurability will not only meet customer expectations but also set the pace for the transition towards intelligent manufacturing. The Early Adapter Programme of R3Group helps to significantly reduce these investments by offering to test R3Group solutions for free.

Don’t miss the chance to test R3GROUP technologies with no investment. Apply today and gain early access, tailored support, and influence over the final solutions, all details to apply here: 👉https://techfinders.io/r3group-early-adopter-programme/

ABOUT THE AUTHOR

Klaus Beetz – R3GROUP Ambassador

Klaus brings over 30 years of experience in software and system engineering, including five years in Eastern Europe. With degrees in mathematics and philosophy, he began his career at Nemetschek AG in the AEC sector.

He has held key roles at European institutions, including trustee at the European Software Institute, executive board member of Digital Europe, and board member of AIOTI.

Since joining Siemens in 2002, Klaus led global research and technology transfer in software-intensive and digital systems. He later served as Director for Business Creation at EIT Digital (2011–2015) and CEO of EIT Manufacturing (2020–2023). Today, he is active as a board member, mentor, and speaker.